Upcoming Events

Stay tuned for more upcoming events!

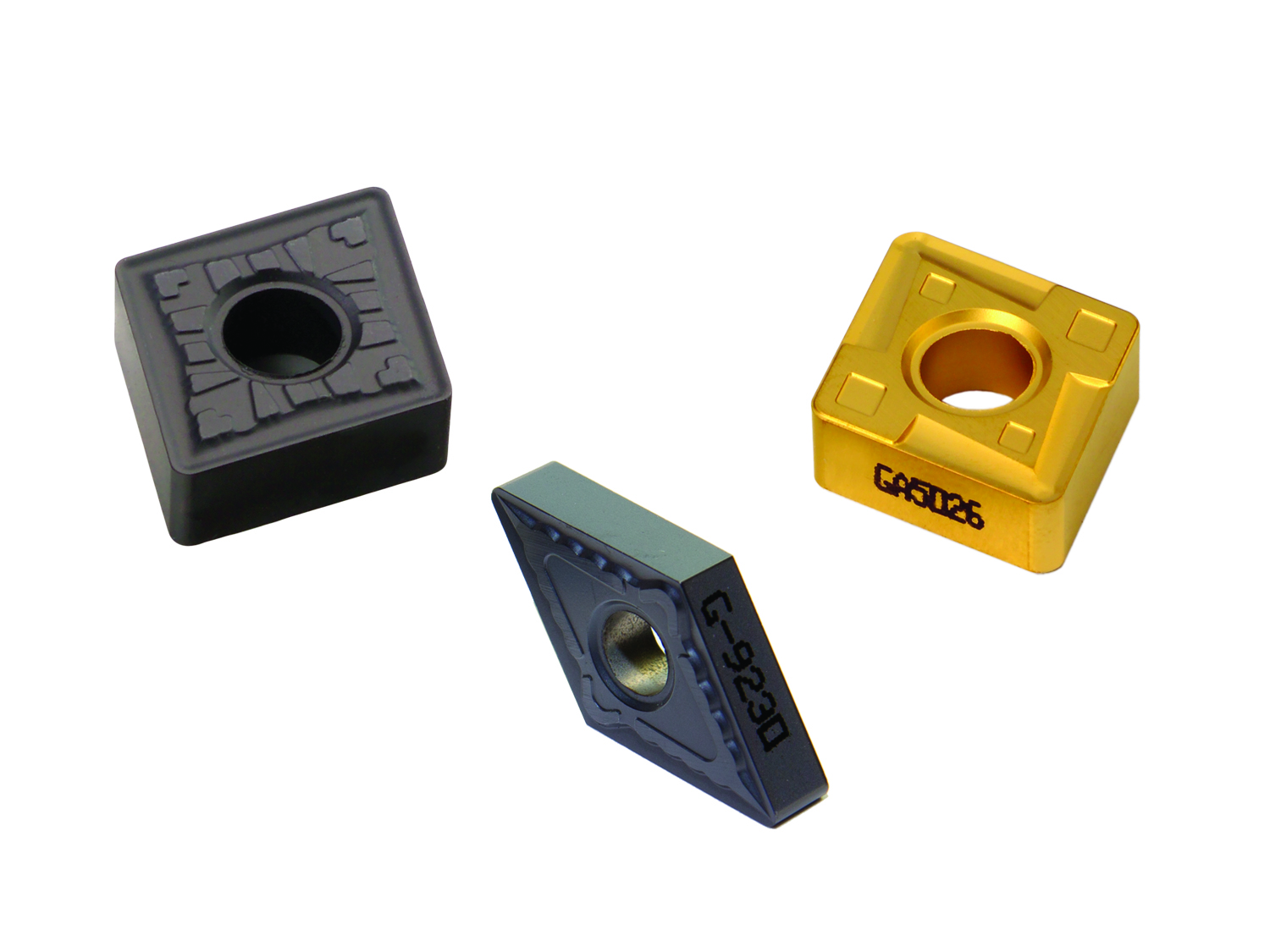

Turning Inserts Face New Challenges

Published December 21, 2020

Martin Dillaman, manager, applications engineering at Greenleaf Corp., Saegertown, Pa., noted the problems that occur with proprietary materials. "We have to discover how materials interact with the substrate and coating. Obviously, the temperature can degrade the insert if it is too high," he said. "The solution is to gain as much information on the material as possible. This is easier with common materials, but proprietary stock supplied by the customer can be extremely difficult in that they often refuse to fully release information about the chemistry and, as a result, we have to depend on trial and error rather than simulation."

Power Parts

Published December 2, 2020

"They're basically a jet engine on steroids," said Greg Bronson, sales director for the Americas, at toolmaker Greenleaf Corppration, Saegertown, PA. Land-based turbines aren't designed with the same concern about weight, he explained, but they still rely on difficult-to-machine materials, especially for the hot sections. That means variations on the nickel-based, heat-resistant Inconels and René materials you'd find in aircraft engines, plus "some proprietary materials specific to OEMs like Siemens and GE," he added.

Innovations in Medical Manufacturing

Published October 28, 2020

Greenleaf Corporation, Saegertown, PA, is also a player in this field, even designing a proprietary holder to enable its tools to cut especially challenging orthopedic features. Joe Presits, sales and service engineer, has recently concentrated on machining shoulder balls and joints in cobalt chrome.

Greenleaf Corporation Launches Quick-Change Toolholders

Published October 1, 2020

Greenleaf Quick-Change toolholders conform to ISO 26623, utilize standard components, and are designed to maximize tool life in carbide and ceramic turning applications.

Greenleaf Corporation Releases GEM-8™

Published May 18, 2020

Greenleaf Corporation is pleased to announce the release of GEM-8™, a new Al2O3 + TiC composite ceramic grade. This new grade will replace our current GEM-7™ product.

Ask The Expert: Questions with Bernie McConnell

Published April 28, 2020

Greenleaf Corporation's Executive Vice President–Commercial discusses ceramics.

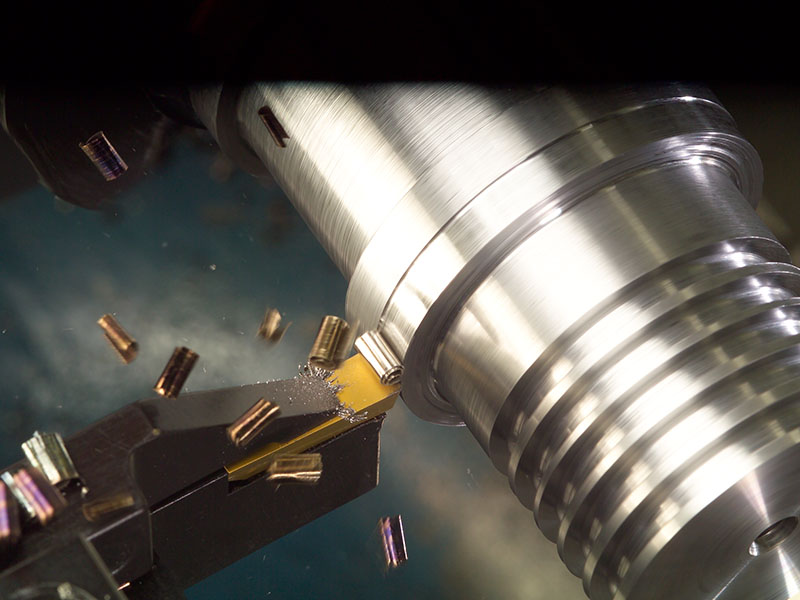

How Indexable Tools Keep Their Edge

Published April 22, 2020

At Greenleaf Corporation, tool designers found that adding more pockets to their face-milling tools actually adds to the life of the inserts in the tools. More inserts stabilize the cut and reduce the forces on each insert, which in turn reduces the number of times the inserts must be indexed, explained Martin Dillaman, Greenleaf's applications engineering manager.

Parting & Grooving: Advanced Tech Delivers Quality Parts, Results

Published February 25, 2020

Greenleaf Corporation offers ceramic and carbide inserts for grooving and cut-off that can be used interchangeably in its toolholders. The benefits of having the choice are obvious for meeting one of the most important customer metrics—lowest cost per part, according to Martin Dillaman, manager applications engineering.

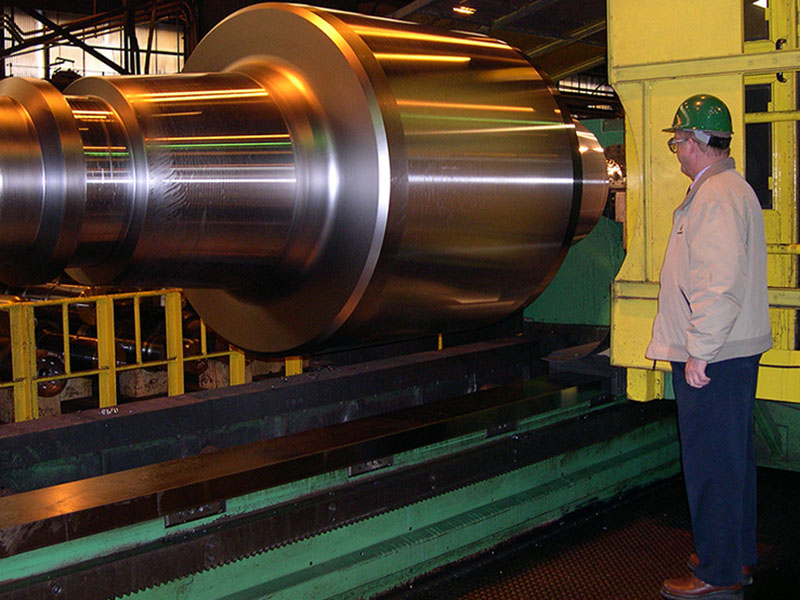

What Makes the Cut in Heavy-Duty Turning?

Published January 7, 2020

"Momentum and inertia can actually pull a crane off the rails, so you must have trained people handling these parts," said Denny Carpenter, a sales and service engineer at Greenleaf Corp., Saegertown, Pa., which manufactures inserts and toolholding systems.