Greenleaf Corporation Product Literature

These brochures and flyers can provide additional information about Greenleaf’s overall product offering and specifically about our ceramic materials for technical and tooling applications.

Aerospace Brochure

Greenleaf Corporation is a world leader in designing, manufacturing, and applying advanced tooling solutions to meet the unique challenges common to manufacturing jet engine components. High nickel alloys, stainless steels, and titanium alloys are all part of our daily application range.

Aerospace BrochureCeramic Productivity Manual

Greenleaf is the industry leader in the development and manufacture of ceramic and coated ceramic inserts in ANSI standard and special geometries. Some of the most prominent include: WG-300®, WG-600®, WG-700™, XSYTIN®-1, GSN100™, and GEM-8™. Learn about guidelines for working with our ceramic materials.

Ceramic Productivity ManualCapstone™-360

The speed and efficiency of solid ceramic end mills with the strength and stability of a carbide shank. Capstone™-360, a new line of high-performance end mills featuring a ceramic tip combined with a carbide shank, offering up to 50% higher tool life compared to most commercially available solid ceramic endmills.

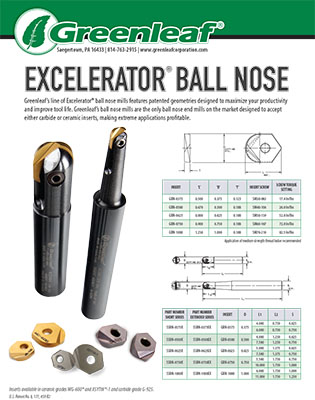

Capstone™-360 FlyerExcelerator® Ball Nose

Greenleaf’s line of Excelerator® ball nose mills features patented geometries designed to maximize your productivity and improve tool life. Greenleaf’s ball nose mills are the only ball nose end mills on the market designed to accept either carbide or ceramic inserts, making extreme applications profitable.

Excelerator® Ball Nose Imperial Excelerator® Ball Nose MetricG5125+

The next generation, high-performance, cobalt-enriched grade that maximizes productivity in roughing and semi-finishing of steels and stainless steels is here! G5125+ is a tough, cobalt-enriched, CVD-coated carbide grade ideally suited for roughing and semi-finishing of steels in turning applications with extended tool life and increased productivity.

G5125+ FlyerG-9610

G-9610 is a PVD-coated carbide grade designed for turning titanium-based alloys. The high-tech, wear-resistant, chemically-stable, and very smooth and lubricious coating protects the heat-resistant, sub-micron substrate and allows for higher speeds and extended tool life in continuous cuts.

G-9610 FlyerGEM-8™

GEM-8 is a next generation aluminum oxide and titanium ceramic composite with increased tool life and a high degree of predictability. Higher strength provides superior edge integrity, making this grade suitable for machining high-strength, high-hardness materials compared to cold-pressed and sintered Al2 O3 (white) ceramics.

GEM-8™ FlyerProduct Guide

Metalcutting tools and systems: Greenleaf Corporation is a leading developer of cutting-tool technology and specializes in the manufacture of high-performance tungsten carbide and ceramic inserts as well as innovative tool-holding systems.

Metalcutting Product GuideQuick-Change Toolholders

ISO 26623 shanks available in C6 and C8 sizes! Greenleaf Quick-Change Toolholders conform to ISO 26623, utilize standard components, and are designed to maximize tool life in carbide and ceramic turning applications.

Quick-Change Toolholders BrochureSolid End Mills

Greenleaf offers solid end mills in both ceramic and carbide! XSYTIN®-360 ceramic end mills offer ten times higher productivity and tremendous cost savings. Greenleaf-360 high-performance carbide end mills have shown speed and feed performance 25-50% higher than the competition with extended tool life.

Solid End Mill CatalogTechnical Ceramics

Trust Greenleaf for all of your technical ceramic needs! Greenleaf has been in the advanced ceramic business for over 50 years, manufacturing ceramic components that work where exotic metals, carbides and traditional ceramics do not perform well. Technical ceramic materials possess properties such as: extreme hardness, strength, and wear resistance, biological compatibility, heat and corrosion resistance, and a wide range of electrical and dielectric properties.

Technical Ceramics Product GuideWhisker-Reinforced Ceramic Inserts

Take your productivity to a new level! Greenleaf whisker-reinforced ceramic inserts are extremely successful at machining hard materials such as hard steels and nickel and cobalt-based super alloys. They offer excellent wear and shock resistance at high surface speeds and are capable of operating up to 10 times the speed that is used for uncoated carbide tools!

Ceramic Inserts BrochureXSYTIN®-1

XSYTIN®-1 — the first of its kind! Phase-toughened ceramics are ceramic-composite cutting tools that offer almost twice the strength of other commercial ceramic-composite cutting tools. Learn how XSYTIN®-1 compares to traditional ceramics and carbide inserts, and see the data on the proven performance of this Greenleaf technology.

XSYTIN®-1 BrochureXSYTIN®-360

XSYTIN®-360 ceramic end mills combine Greenleaf's phase-toughened XSYTIN®-1 substrate with a unique cutting geometry that offers ten times higher productivity and tremendous cost savings. These new ceramic end mills provide customers with significant increases in productivity over current solid carbide or ceramic products.

XSYTIN®-360 Brochure