Upcoming Events

EMO • Hannover, Germany

September 22-26

Hall 4, Stand E24

emo-hannover.com

WESTEC • Anaheim, CA

October 7-9 | Booth #1823

west.mtseries.com

SOUTHTEC • Greenville, SC

October 21-23 | Booth #1021

southeast.mtseries.com

HOUSTEX • Dallas, TX

November 4-6 | Booth #203

southwest.mtseries.com

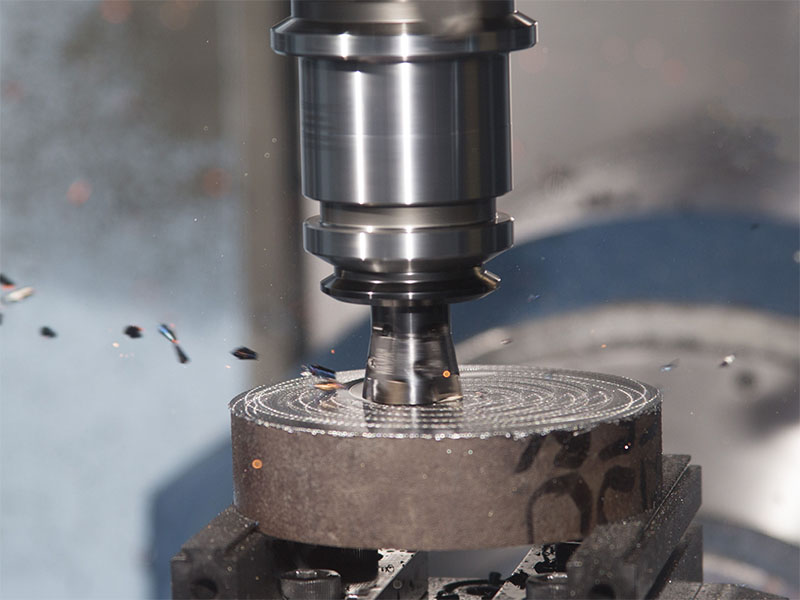

Energy Parts Machining

Published November 7, 2019

"…every second the part is at the spindle is critical. The material removal rates that our inserts and tooling offer can reduce operations that took hours to just minutes." – Martin Dillaman, manager of applications engineering for Greenleaf Corporation on the efficiency of Greenleaf ceramic inserts for machining parts for the energy industry.

General McLane to Graduate First Manufacturing Academy Class

Published April 21, 2019

"I always knew that I wanted to be a machinist...As part of this program, I started going to companies to see what they’re like in sophomore year. I wanted to get experience and go on to a full-time job. I had heard a lot of great things about Greenleaf, and it’s a great work environment."

Phase-Toughened Ceramics: The Next Revolution in Machining of Heat-Resistant Super Alloys

Published March 2019

As a means of large-scale production, metal machining mostly developed throughout the 19th century, playing a significant role in the second industrial revolution and facilitating the manufacturing boom that fueled the technological expansion of the 20th century [...] Increasing temperatures and stresses in gas turbines (among others) led to the development of nickel- and cobalt-based heat-resistant super alloys (HRSA), and while cemented tungsten carbide tools continued to improve – the rapidly evolving properties of HRSAs meant that carbide machining was, respectively, becoming less and less efficient.