Upcoming Events

EMO • Hannover, Germany

September 22-26

Hall 4, Stand E24

emo-hannover.com

WESTEC • Anaheim, CA

October 7-9 | Booth #1823

west.mtseries.com

SOUTHTEC • Greenville, SC

October 21-23 | Booth #1021

southeast.mtseries.com

HOUSTEX • Dallas, TX

November 4-6 | Booth #203

southwest.mtseries.com

Greenleaf Introduces G-9610: A New Carbide Insert Grade for Machining Titanium

Published December 7th, 2021

Today Greenleaf announced the release of a new, advanced, titanium turning grade: G-9610. G-9610 is a PVD-coated carbide grade designed for turning titanium-based alloys. The high-tech, wear-resistant, chemically-stable, and very smooth and lubricious coating protects the heat-resistant, sub-micron substrate and allows for higher speeds and extended tool life in continuous cuts.

Toolmakers Target Tough Alloys

Published December 2, 2021

“[We see] HRSAs as all nickel- and cobalt-based alloys that exploit the yield-strength anomaly," noted Alex Minich, applications engineer at toolmaker Greenleaf Corp., Saegertown, Pa. He is referring to when yield strength increases with temperature, contrary to most materials that get softer as they get hotter, or lower yield strength. It seems to be an anomaly—hence the name.

Ask the Expert: Bernie McConnell

Published August 30, 2021

Greenleaf Corp. Executive Vice President – Commercial Bernie McConnell answers questions about two new technologies.

An Improbable but Powerful Solution

Published June 23, 2021

One such “hotter is better” success story comes from Greenleaf Corp., Saegertown, Pa., where a customer reportedly reduced cycle time by an incredible 97 percent when milling a block of Inconel 625. “Previously, it required three solid-carbide end mills and more than 90 minutes to machine the part,” said Martin Dillaman, applications engineering manager for Greenleaf. “After switching to our XSYTIN-360 solid-ceramic end mill, it took just three minutes.”

Ceramic End Mill Achieves Long Life and High MRR at Standard Machining Center Speeds

Published June 4, 2021

According to James Greenleaf, the third-generation owner of the company, these tools are “the most extensively tested product we have ever introduced.” And that testing continues, because a ceramic tool with greater toughness is a tool that potentially has promise within machining sectors and applications not typically associated with ceramics, involving shops that have not turned to ceramic tooling before.

Toolholding: Built for Speed

Published May 27, 2021

Matt Goss, applications engineer/project development for Greenleaf Corp., Saegertown, Pa., said his company considers high speed to be a combination of two factors: high spindle speed and a high feed rate. “This translates to a high feed speed (ipm), which helps to not only maximize the amount of material removed, but also leads to reduced cycle times.”

Innovation in Ceramic End Milling

Published May 1, 2021

Compared to carbide end mills, XSYTIN®-360 offers all of the advantages of ceramic machining with few of the drawbacks. In difficult materials – heat-resistant alloys and any alloys with a high hardness especially – XSYTIN®-360 has the ability to reduce cycle times by a factor of 10 or more.

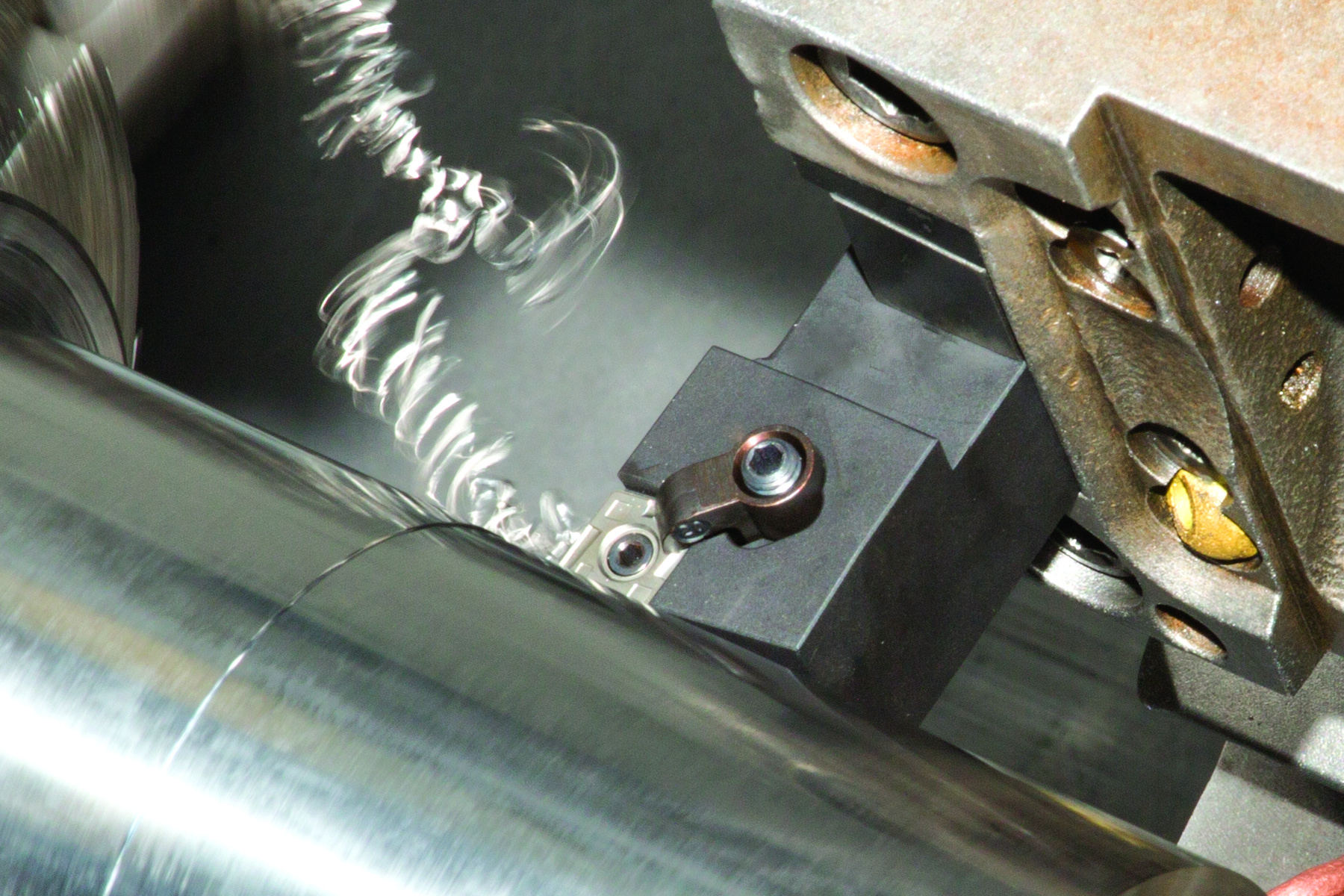

New Tech Powers Productivity Gains in Indexable Milling

Published April 26, 2021

Whether it’s used for liquid or air coolant, you need a controlled flow out to the cutting edge to help prevent chips from building up and also for evacuating the chips out of the area where the next insert will be coming through to cut. That prevents possible recutting or packing of chips into the flutes and helps overall performance and finish.

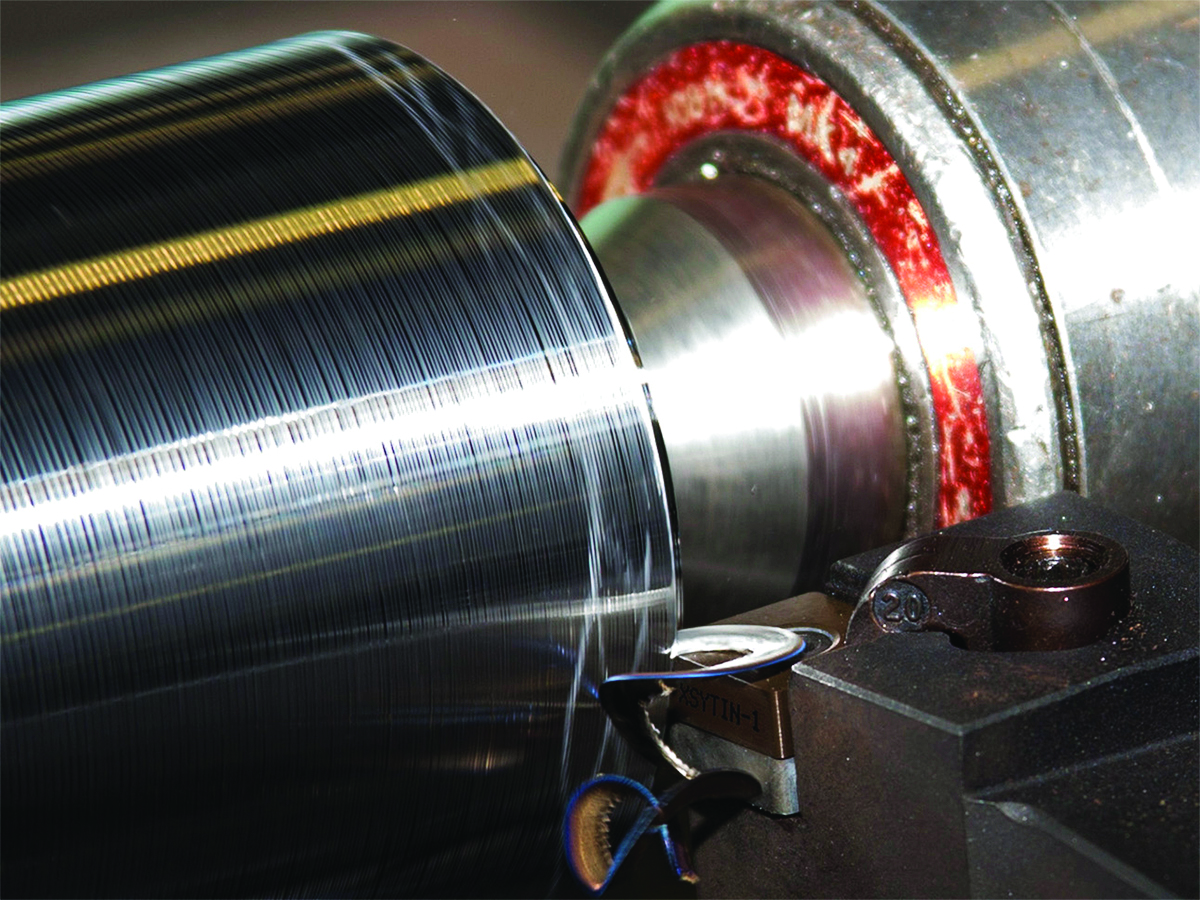

The Keys to Improve Turning Finish

Published March 1, 2021

Roughing should remove enough material so that the finishing tool is not cutting over the radius. [...] Roughing operations tend to use heavier feeds, which can lead to scallops on the walls of the shoulder. These scallops can be very hard and lead to very poor insert life if they are found on the part during finishing operations.

Greenleaf Introduces XSYTIN®-360 New Solid Ceramic End Mills

Published February 9, 2021

Greenleaf Corporation today announced XSYTIN®-360, a new line of high-performance solid ceramic end mills, to the global market. XSYTIN®-360 end mills combine Greenleaf’s phase-toughened XSYTIN®-1 substrate with a unique cutting geometry that offers ten times higher productivity and tremendous cost savings.

Greenleaf Corporation Launches New Website

Published February 1, 2021

...In addition to browsing the Greenleaf catalogs and other literature for product and technical information, visitors to the site can now read about Greenleaf’s history, employment opportunities, news, and events...

Embracing Slot Diversity

Published January 5, 2021

"Bronson said Greenleaf designs cutters that go into curved shapes, 'which is a challenge because you don’t have a straight line of sight through that slot like you would with traditional slotting. The tool is a little unusual. When you look at the side profile of a contact lens, it’s dished; that’s the shape of the cutter.'"